When you have a classic Chevy 350 engine, getting it to run just right is a special kind of satisfaction, isn't it? There's nothing quite like the sound of a well-tuned small block. Yet, sometimes, things go a bit sideways, and you find yourself scratching your head, perhaps with ignition wires scattered about. It happens, and it can be pretty frustrating, especially if you've had some bad information along the way.

Maybe you're planning to swap out your old ignition wires, or perhaps you've recently upgraded from a points system to something like an HEI setup. Whatever the reason, if your engine isn't quite purring, or if it's misfiring in a way that just feels wrong, the firing order is often one of the first things to check. It's a fundamental piece of the puzzle, you know, for making sure everything fires at the precise moment it should.

A lot of folks, like me, have been there, trying to sort out why a beloved 350 Chevy, maybe a '70 El Camino, just isn't performing. It can feel like a bit of a mystery when wires are off the distributor cap and you're not sure where to begin putting them back. But with a little guidance, and some tried-and-true methods, you can get your engine singing again, and that's what we're here to help you do today.

Table of Contents

- What Exactly is Firing Order?

- The Classic Chevy 350 Firing Sequence

- Wiring Your Distributor Cap

- Troubleshooting Common Firing Order Problems

- The New GM Firing Order: A Look at Durability

- Frequently Asked Questions About Chevy 350 Firing Order

- Getting Your Engine Back on Track

What Exactly is Firing Order?

At its core, the firing order is just the sequence in which your engine's cylinders ignite their air-fuel mixture. Think of it like a carefully choreographed dance for the pistons. Each cylinder needs to fire at a very specific moment to create a smooth, powerful rotation of the crankshaft. If the timing is off, or if the order is wrong, your engine won't run right, or it might not run at all. It's a pretty big deal, you know, for the engine's health and how it performs.

This precise sequence helps balance the engine's forces, making sure it runs smoothly and without too much vibration. Without the right firing order, you could experience anything from a rough idle to a complete inability to start. It's really that important, and getting it right is a key step in keeping your engine happy. So, understanding this sequence is a must for anyone working on their small block Chevy.

The Classic Chevy 350 Firing Sequence

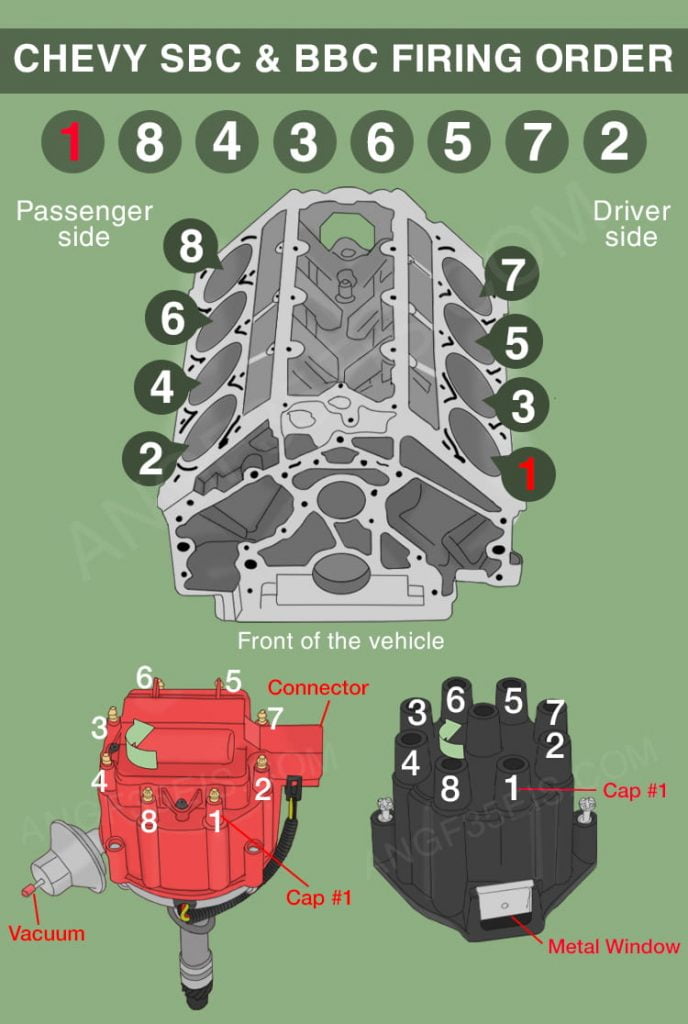

For most traditional small block Chevy 350 engines, the standard firing order is 1-8-4-3-6-5-7-2. This sequence means cylinder number one fires first, then cylinder eight, then four, and so on, until cylinder two fires, and the cycle begins again. It's a well-established pattern that has served these engines well for decades. Knowing this specific number string is, in a way, your secret code for proper ignition setup, and it's something you'll want to commit to memory or keep handy.

Remembering this order is a crucial first step when you're working on your ignition system. If you've ever had a situation where your wires are completely off the cap, and you're just staring at an empty distributor, this sequence is your guide. It's the blueprint, so to speak, that tells you exactly where each spark plug wire needs to go on the distributor cap to send power to the right cylinder at the right time. It's a bit like putting together a puzzle, and this is the picture on the box.

Finding Cylinder Number One

Before you can even begin connecting wires, you need to know which cylinder is number one. On a Chevy small block, cylinder number one is the front-most cylinder on the driver's side of the engine. That's the left side as you're sitting in the car, or the right side if you're standing in front of the engine looking back. It's a pretty straightforward thing once you know, but it's a common point of confusion for some folks, so it's good to be clear.

To truly get things right, you'll need to find Top Dead Center (TDC) for cylinder number one on its compression stroke. This is when both valves for that cylinder are closed, and the piston is at the very top of its travel. Once you've got cylinder one at TDC on the compression stroke, you can then see where the distributor rotor is pointing. That's where your number one spark plug wire will connect on the distributor cap. This procedure has worked perfectly for me for years, and it's a very reliable way to start fresh.

Distributor Cap Orientation

Once you've found cylinder number one's position on the distributor cap, the rest of the wiring becomes much easier. Many people find that the number one spark plug wire often plugs into the distributor cap on the Delco HEI system for a 350 Chevy at around the 5:30 position, as you're looking from the front of the motor. This is a pretty common spot, but it's not a hard and fast rule for every setup, so it's important to verify it with your specific engine's TDC. It's a good starting point, though, to get a general idea.

From that number one spot, you'll then follow the distributor's rotation to connect the rest of the wires according to the 1-8-4-3-6-5-7-2 firing order. Knowing this general orientation can save you a lot of guesswork and frustration, especially if your wires are completely off the cap and you're just trying to put things back together. It's a bit like having a compass when you're trying to find your way, really.

Wiring Your Distributor Cap

Once you've identified cylinder number one and its corresponding terminal on the distributor cap, you're ready to connect the rest of the wires. It's a systematic process, and taking your time here will save you headaches later on. If you are planning to replace your ignition wires, always do it one at a time if you can, just to avoid mixing things up. This little tip can make a big difference, you know, in keeping things straight.

Start with the number one wire, running it from the spark plug to the appropriate spot on the cap. Then, moving in the direction the rotor turns, connect the wire for cylinder eight to the next terminal in the sequence. Continue this pattern for cylinders four, three, six, five, seven, and finally, two. Double-checking each connection as you go is a very good idea, as a single misplaced wire can cause a whole host of running issues. It's a simple step, but one that truly matters.

Rotor Direction Matters

The rotor inside your distributor spins in a specific direction, and this is absolutely key to getting the wires connected correctly. For most Chevy small block distributors, the rotor turns clockwise. This means that after you've placed your number one wire, you'll connect the next wire in the firing order (cylinder eight) to the terminal immediately clockwise from number one. It's a small detail, but it's one that can really throw you off if you get it wrong, so pay attention to it.

If you're unsure of your rotor's direction, you can always briefly crank the engine with the cap off (and spark disabled for safety, of course) to observe which way the rotor spins. This quick check can confirm your understanding and help you avoid a miswired setup. It's a simple test that provides a lot of peace of mind, really, before you commit to all the wiring.

From Points to HEI: Does the Order Change?

A common question arises when people upgrade their ignition system, say from old points to a modern HEI (High Energy Ignition) unit. Do I use the same wire firing order to dizzy cap as the old points configuration? The answer, thankfully, is yes. The firing order itself is determined by the engine's crankshaft and camshaft design, not by the type of ignition system. So, the 1-8-4-3-6-5-7-2 sequence remains the same for your Chevy 350, regardless of whether you're running points or HEI. It's a pretty consistent thing, which is nice.

What changes with an HEI system is how the spark is generated and delivered, which is usually much more powerful and reliable. But the order in which those sparks are sent to the cylinders stays put. So, if you've upgraded from points to HEI on a Chevy 327 or 350 cubic inch engine, you can rest easy knowing that the fundamental firing order you're familiar with is still the one you need to use. It's one less thing to worry about, and that's always a good thing.

Troubleshooting Common Firing Order Problems

Even with the correct firing order in mind, sometimes things just don't run as they should. You might have a rough idle, a lack of power, or even a backfire. These symptoms often point back to an issue with the ignition system, and a miswired firing order is a frequent culprit. It's a common headache for many mechanics, both professional and amateur, so you're certainly not alone if you're dealing with it.

One person mentioned that they trusted someone with some info on firing order for their 350 Chevy (a '70 Elco), which was a bad idea and went completely wrong. Their wires were off the cap and they were unable to figure it out. This highlights how easily things can go awry with incorrect information. It really emphasizes the need for accurate details when working on something as precise as an engine's ignition. It's a bit like following a recipe, where one wrong ingredient can spoil the whole dish.

Misfires and What They Tell You

If your engine isn't pulling its weight, or if it feels like every other cylinder in the firing order isn't firing correctly at idle, you might have misfires. For instance, if cylinders 3, 5, 2, and 8 aren't contributing much, and you can pull the wires at the cap on these cylinders and it doesn't get worse, that's a pretty strong sign of a problem with those specific cylinders or their connections. This kind of pattern can often point to a wiring mistake, or perhaps an issue with the spark plugs or ignition coils for those cylinders. It's a very telling sign, you know, of what's going on inside.

When troubleshooting misfires, it's always a good idea to re-check your firing order against the standard 1-8-4-3-6-5-7-2. A single wire swapped can cause multiple cylinders to misfire in an odd pattern, making it seem more complex than it is. Sometimes, it's just a matter of carefully tracing each wire from the spark plug back to its correct spot on the distributor cap. It's a bit tedious, perhaps, but it's a very effective way to find the issue.

The Valve Adjustment Connection

Interestingly, the firing order also ties into other engine maintenance tasks, like valve adjustment. There's a procedure where you adjust the valves in the cylinder opposite the cylinder in the firing order that's at TDC. This method helps ensure that the valves are properly set when the cylinder is not under compression or firing, allowing for accurate adjustment. It's a clever way to work through the engine, making sure each valve gets its proper setting.

This procedure has worked perfectly for many for years, and it's something many wish everyone would try. It's a testament to how interconnected all the parts of an engine truly are. So, while you're thinking about firing order, remember that it plays a role in other aspects of engine setup and tuning, too. It's all part of the bigger picture of a well-running machine, you know.

The New GM Firing Order: A Look at Durability

While the classic Chevy 350 uses the 1-8-4-3-6-5-7-2 firing order, there's also talk about a "new GM firing order," often associated with more modern engines like the LS series. This newer order is 1-8-7-2-6-5-4-3. The reason for this change is quite interesting: it moves the major stresses of successive firing across the same main cap to the rear of the engine, which typically gets oiled first. This design change aims for better durability and less wear on the engine's main bearings. It's a pretty smart engineering move, really.

Now, it's important to understand that you can't just apply this new firing order to a stock classic Chevy 350. The engine's camshaft and crankshaft are designed for the original order. However, for those building highly customized or performance-oriented 350s, sometimes a specialized camshaft can be used to adapt the engine to this newer, more durable firing sequence. It's a very advanced modification, though, and not for the faint of heart. But it shows how much thought goes into making engines last longer and perform better, you know, with every little detail.

Frequently Asked Questions About Chevy 350 Firing Order

Here are some common questions people often have when dealing with their Chevy 350's firing order:

What happens if my Chevy 350 firing order is wrong?

If your Chevy 350 firing order is incorrect, you'll likely experience a very rough idle, significant loss of power, backfiring through the carburetor or exhaust, and the engine might not even start at all. It can also cause engine damage over time if run for too long in this state. It's a pretty clear sign something's off, you know, when the engine just doesn't feel right.

How do I find the #1 cylinder wire on my Chevy 350 distributor cap?

To find the #1 cylinder wire on your Chevy 350 distributor cap, first bring cylinder #1 to Top Dead Center (TDC) on its compression stroke. Then, remove the distributor cap and observe where the rotor is pointing. That terminal on the cap is where your #1 spark plug wire connects. As a general guide, it's often around the 5:30 position when you're looking at the engine from the front, but confirming with TDC is always the best way. It's a very reliable method, for sure.

Does converting to HEI change the Chevy 350 firing order?

No, converting your Chevy 350 from a points ignition system to an HEI system does not change the engine's firing order. The firing order (1-8-4-3-6-5-7-2) is set by the engine's internal design, specifically the camshaft and crankshaft. The HEI system simply provides a more efficient and powerful spark, but it delivers that spark to the cylinders in the same sequence as the original points system. So, you can use the same wire firing order to your distributor cap as the old points configuration. It's a pretty consistent thing, actually.

Getting Your Engine Back on Track

Getting the firing order right on your Chevy 350 is a truly satisfying moment. It's a bit like solving a puzzle, and the reward is a smooth-running engine that responds the way it should. Whether you're dealing with misfires, replacing wires, or just wanting to be sure everything is set up properly, knowing the correct sequence and how to apply it is absolutely key. It can save you a lot of frustration and make your time with your classic machine much more enjoyable. This procedure, you know, has worked perfectly for me for years, and it truly helps.

Remember, a little patience and careful attention to detail go a long way when you're working on your engine's ignition. If you're struggling, don't hesitate to consult a good repair manual or seek advice from experienced enthusiasts. There's a lot of collective wisdom out there, and sharing it helps everyone keep these great engines on the road. For more engine wisdom, you can learn more about engine basics on our site, or perhaps explore tips for optimizing engine performance for your classic ride. Happy wrenching, and here's to many more miles of smooth cruising!

Detail Author:

- Name : Kaley Swift MD

- Username : camryn35

- Email : crunte@yahoo.com

- Birthdate : 1987-12-13

- Address : 6508 Wolf Junctions Apt. 568 Groverborough, VT 86869-9902

- Phone : +1-838-307-0582

- Company : Beer Ltd

- Job : Fire Inspector

- Bio : Accusantium aspernatur accusantium saepe. Fuga quam ducimus quis assumenda. Facilis dolore tempora eveniet quasi dolorum enim. Incidunt animi adipisci non autem quia aut.

Socials

instagram:

- url : https://instagram.com/krisa

- username : krisa

- bio : Fuga ad ab voluptatem aut aut qui. Sint corrupti iusto consequatur delectus.

- followers : 5207

- following : 1521

linkedin:

- url : https://linkedin.com/in/alvah_official

- username : alvah_official

- bio : Vel animi eum exercitationem ut.

- followers : 2269

- following : 1503